推薦產(chǎn)品

聯(lián)系我們

熱線:0531-84223080

手機(jī):188-5310-7177 高經(jīng)理

手機(jī):188-8831-9177 王凱

郵編:251400

地址:濟(jì)南市濟(jì)陽(yáng)縣濟(jì)北開發(fā)區(qū)黃河大街智造小鎮(zhèn)G1

新聞中心

濟(jì)南模具加工需要注意的幾點(diǎn)事項(xiàng)

瀏覽次數(shù):908 發(fā)表時(shí)間:2017-04-25 17:31:55濟(jì)南模具加工是塑料加工工業(yè)中和塑料成型機(jī)配套,賦予塑料制品以完整構(gòu)型和精確尺寸的工具。由于塑料品種和加工方法繁多,塑料成型機(jī)和塑料制品的結(jié)構(gòu)又繁簡(jiǎn)不一,所以濟(jì)南模具加工的種類和結(jié)構(gòu)也是多種多樣的。那么,我們?cè)谠O(shè)計(jì)濟(jì)南模具加工時(shí),都需要注意哪些要點(diǎn)呢?Ji'nan mold processing is the plastic processing industry and plastic molding machine, plastic products to complete configuration and precise size tools. Because of the plastic varieties and processing methods of various plastic molding machine and plastic product structure is simplified, so Ji'nan mold type and structure is various. So, we in the design of Ji'nan mold processing, need to pay attention to what points?

1.開模方向。濟(jì)南塑料模具的開模方向確定后,可選擇適當(dāng)?shù)姆中途€,避免開模方向存在倒扣,以改善外觀及性能。濟(jì)南塑料模具的開模方向確定后,產(chǎn)品的加強(qiáng)筋、卡扣、凸起等結(jié)構(gòu)盡可能設(shè)計(jì)成與開模方向一致,以避免抽芯減少拼縫線,延長(zhǎng)模具壽命。Opening direction. Ji'nan plastic mold after the mold direction is determined, you can choose the appropriate parting line, to avoid the opening direction of the existing button to improve the appearance and performance. Ji'nan plastic mold parting direction, product rib, buckle, convex structure as much as possible consistent with the direction of mold design, in order to avoid pulling reduce joint line, prolongs the service life of the mould.

2.產(chǎn)品壁厚。濟(jì)南模具加工的壁厚不均會(huì)引起氣孔和熔接痕。濟(jì)南塑料模具的壁厚不均會(huì)引起塑膠產(chǎn)品表面縮水。各種塑料均有一定的壁厚范圍,一般0.5~4mm,當(dāng)壁厚超過(guò)4mm時(shí),將引起冷卻時(shí)間過(guò)長(zhǎng),產(chǎn)生縮印等問題,應(yīng)考慮改變產(chǎn)品結(jié)構(gòu)。Product wall thickness. The uneven thickness of the die in Ji'nan will cause the pores and the weld marks. The uneven thickness of plastic mold in Ji'nan will cause the shrink of plastic products. All kinds of plastic has a certain thickness range of 0.5~4mm, when the wall thickness is more than 4mm, will cause the cooling time is too long, which reduce and other issues, should consider changing the product structure.

3.扣位。將濟(jì)南模具加工的扣位裝置設(shè)計(jì)成多個(gè)扣位同時(shí)共用,使整體的裝置不會(huì)因?yàn)閭€(gè)別扣位的損壞而不能運(yùn)作,從而增加其使用壽命,再是多考濾加圓角,增加強(qiáng)度。濟(jì)南塑料模具的扣位相關(guān)尺寸的公差要求十分嚴(yán)謹(jǐn),倒扣位置過(guò)多容易形成扣位損壞;相反,倒扣位置過(guò)少則裝配位置難於控制或組合部份出現(xiàn)過(guò)松的現(xiàn)象。解決辦法是要預(yù)留改模容易加膠的方式來(lái)實(shí)現(xiàn)。Buckle position. Ji'nan mold locking device design into a plurality of buckling and sharing, so that the overall device will not buckle because individual bit damaged and not operation, thereby increasing its service life, and is admitted to filter radius, increase strength. Ji'nan plastic mold buckle a size tolerance requirements are very strict, inverted position too easy to form buckling damage; on the contrary, the inverted position is too difficult to control the assembly position or combination part appeared loose phenomenon. The solution is to modify the mold to be easy to add glue to achieve.

4.脫模斜度。濟(jì)南模具加工廠家認(rèn)為,適當(dāng)?shù)拿撃P倍瓤杀苊猱a(chǎn)品拉毛(拉花)。光滑表面的脫模斜度應(yīng)該小于0.5度,細(xì)皮紋(砂面)表面大于1度,粗皮紋表面大于1.5度。適當(dāng)?shù)拿撃P倍瓤杀苊猱a(chǎn)品頂傷,如頂白、頂變形、頂破。深腔結(jié)構(gòu)產(chǎn)品設(shè)計(jì)時(shí)外表面斜度盡量要求大于內(nèi)表面斜度,以保證注塑時(shí)模具型芯不偏位,得到均勻的產(chǎn)品壁厚,并保證產(chǎn)品開口部位的材料強(qiáng)度。Stripping slope. Ji'nan mold processing factory, draft the appropriate products to avoid picking (Garland). The smooth surface should be less than 0.5 degrees, and the fine grain (sand) surface is more than 1 degrees, and the coarse grain surface is more than 1.5 degrees. Appropriate stripping slope can avoid the product top injury, such as top white, top deformation, top broken. In the design of the deep cavity structure, the external surface slope should be greater than the inner surface slope, so as to ensure that the die core is not biased, and the uniform product thickness is obtained.

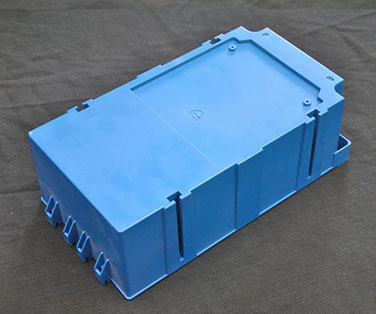

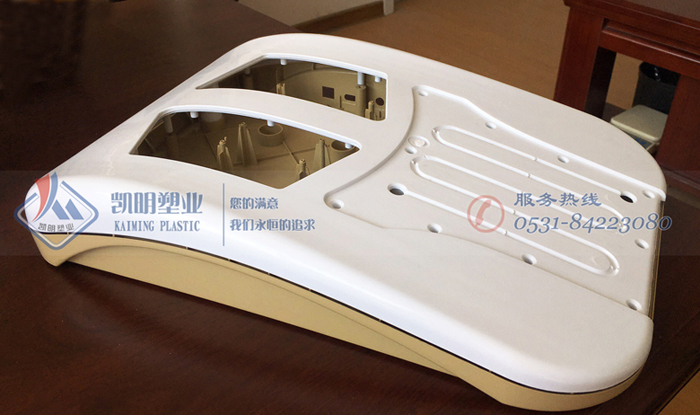

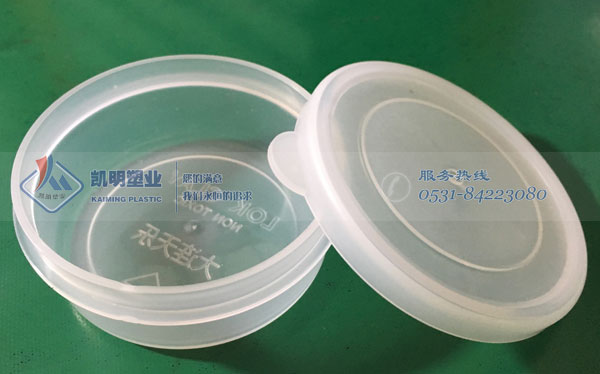

推薦注塑加工產(chǎn)品

推薦注塑加工資訊

- 注塑加工制品分層、無(wú)光澤有哪些原因?

- 濟(jì)南模具加工中排氣結(jié)構(gòu)如何設(shè)計(jì)?

- 注塑加工行業(yè)的價(jià)格為什么會(huì)上漲

- 濟(jì)南注塑加工壁厚的尺寸應(yīng)當(dāng)符合哪些要求?

- 山東注塑加工的異味如何避免?

- 山東模具加工調(diào)試前如何做好準(zhǔn)備?

- 山東模具加工機(jī)器操作應(yīng)該注意哪些問題?

- 怎么樣才能搞明白濟(jì)南注塑模具加工費(fèi)用?

- 濟(jì)南注塑加工廠要如何預(yù)防模具生銹呢?

- 濟(jì)南注塑模具行業(yè)的相關(guān)知識(shí)介紹

- 注塑加工中出現(xiàn)溶接痕如何改善?

- 山東注塑加工停機(jī)重啟需要注意什么?

- 怎么有效的提高濟(jì)南注塑加工效率?

- 濟(jì)南注塑加工零件外觀的四個(gè)影響因素

- 濟(jì)南電子產(chǎn)品注塑模具在試模會(huì)遇到哪些問題

- 山東模具加工過(guò)程中出現(xiàn)氣泡的原因?

- 山東模具加工影響模具表面拋光性的因素

- 濟(jì)南注塑加工廠介紹開藍(lán)牙耳機(jī)注塑模具周期提前50%的秘密!

- 濟(jì)南注塑加工廠淺談注塑行業(yè)中塑料和塑膠的不同之處

- 濟(jì)南注塑模具加工驗(yàn)收流程是怎么做的?