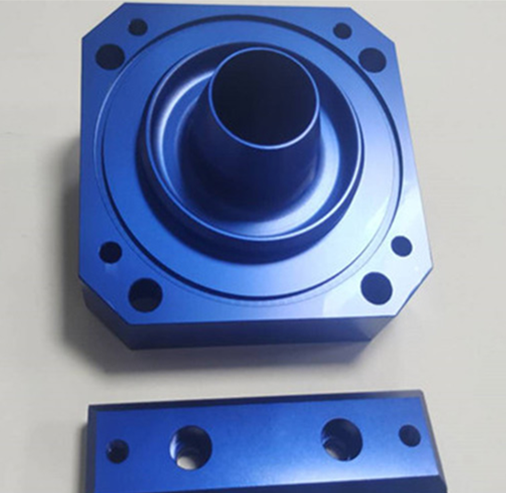

推薦產(chǎn)品

聯(lián)系我們

熱線:0531-84223080

手機:188-5310-7177 高經(jīng)理

手機:188-8831-9177 王凱

郵編:251400

地址:濟南市濟陽縣濟北開發(fā)區(qū)黃河大街智造小鎮(zhèn)G1

新聞中心

山東注塑加工一般選擇什么原料?

瀏覽次數(shù):950 發(fā)表時間:2017-02-09 10:51:021.山東注塑加工 http://www.patentattorney.cn/的原料混有其它雜質(zhì)或摻雜了不適當?shù)幕蜻^量的溶劑或其它添加劑時。In Shandong, the raw materials of the injection molding process are mixed with other impurities or adulterated with inappropriate or excessive solvents or other additives.

2.有些塑料如ABS等,在受潮狀況下加熱會與水汽發(fā)生催化裂化反應,使山東注塑加工制件發(fā)生大的應變。Some plastics, such as ABS and so on, under the condition of damp heat and water vapor catalytic cracking reaction, so that the injection molding parts of Shandong.

3.塑料再生次數(shù)太多或再生料含量太高,或在山東注塑加工機筒內(nèi)加熱時間太長,都會促使制件脆裂。Too many times of recycled plastic or recycled material content is too high, or in Shandong injection molding machine barrel heating time is too long, will promote the brittle crack.

4.塑料本身質(zhì)量不佳,例如分子量分布大,含有剛性分子鏈等不均勻結(jié)構(gòu)的成分占有量過大;或受其它塑料摻雜污染、不良添加劑污染、灰塵雜質(zhì)污染等是造成山東注塑加工發(fā)脆的原因。The plastic is of poor quality, such as large molecular weight distribution, with rigid molecular chain structure of the components such as uneven amount is too large; or doping by other plastic pollution, poor additive pollution, dust impurities pollution is the cause of Shandong injection molding crisp.

- 上一篇:濟南模具加工中的散熱問題如何解決?

- 下一篇:山東模具加工廠談模具失效的原因

推薦注塑加工產(chǎn)品

推薦注塑加工資訊

- 濟南注塑加工廠注塑車間安全生產(chǎn)規(guī)定

- 濟南注塑加工的精度如何提高?

- 濟南注塑模具設計加工如何做?

- 濟南注塑加工廠要如何預防模具生銹呢?

- 山東模具加工有哪些特點?

- 解析注塑加工需要注意事項

- 如何解決濟南注塑加工過程中注塑件硬化速度的問題

- 山東注塑加工工藝改善的必要性

- 山東模具加工影響模具表面拋光性的因素

- 濟南注塑模具制品廠色粉如何管理

- 塑料制品加工過程中廢氣如何處理?

- 濟南注塑加工過程中必然要注意的三個問題

- 注塑加工時氣味重怎么辦?

- 濟南注塑加工產(chǎn)品溫度的重要性

- 注塑加工過程中須注意的操作細節(jié)

- 注塑加工的試模步驟有哪些?

- 注塑加工有哪些輔助設備?

- 山東塑料制品加工廠談塑料制品的優(yōu)勢

- 濟南注塑加工添加母料后產(chǎn)品斷裂應該怎么辦?

- 山東模具加工顏色不穩(wěn)定的原因有哪些?