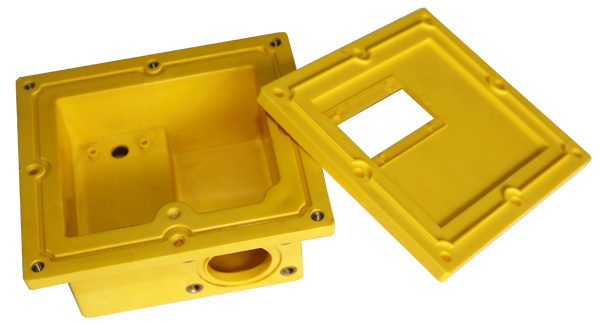

推薦產(chǎn)品

聯(lián)系我們

熱線:0531-84223080

手機(jī):188-5310-7177 高經(jīng)理

手機(jī):188-8831-9177 王凱

郵編:251400

地址:濟(jì)南市濟(jì)陽(yáng)縣濟(jì)北開(kāi)發(fā)區(qū)黃河大街智造小鎮(zhèn)G1

新聞中心

如何提高濟(jì)南模具加工的精度工藝?

瀏覽次數(shù):851 發(fā)表時(shí)間:2017-04-27 15:17:20要提升濟(jì)南模具加工的精密度,條件有很多,其中最本質(zhì)的是塑料材料、注塑模具、注塑工藝和注塑設(shè)備這四項(xiàng)基本因素。我們?cè)O(shè)計(jì)塑料外殼模具時(shí),應(yīng)首先選定工程塑料材料,而能進(jìn)行精密塑料外殼加工的工程塑料又必須選用那些力學(xué)性能高、尺寸穩(wěn)定、抗蠕變性能好、耐環(huán)境應(yīng)力開(kāi)裂的材料。其次應(yīng)根據(jù)所選擇的塑料材料、成品尺寸精度、件重、質(zhì)量要求以及預(yù)想的模具結(jié)構(gòu)選用適用的注塑機(jī)。To improve the precision of the mold processing in Ji'nan, there are many conditions, the most essential is the plastic materials, injection mold, injection molding process and injection molding equipment, these four basic factors. We design the plastic shell mold, should be first selected engineering plastics materials, and can carry out precision plastic shell processing engineering plastics must choose those high mechanical properties, dimensional stability, good creep resistance, environmental stress cracking resistance of materials. Second, according to the selection of plastic materials, product size precision, weight, quality requirements and the expected mold structure to choose the appropriate injection molding machine.

1.關(guān)模壓:濟(jì)南模具加工原則上應(yīng)大于塑膠射入模內(nèi)的總壓,以不出毛邊為基準(zhǔn)。Mold closing: Ji'nan mold processing principle should be greater than the plastic injection mold in the total pressure, with no burr as the benchmark.

2.壓力和速度:壓力和速度有部分相同的關(guān)系作用于模內(nèi)。目的使原料進(jìn)入模內(nèi)能均勻,徹底,適量的充滿各角落.太低會(huì)短射,縮水,太高有毛頭,過(guò)飽,粘模,燒焦,易損模具及內(nèi)應(yīng)力高等不良現(xiàn)象。Pressure and speed: pressure and velocity have the same effect on the mold. Objective to make the raw material into the mold can be uniform, thorough, full of every corner. The amount is too low will shrink, short shot, too high a feather, satiety, sticking, burning, and internal force of die wearing higher adverse phenomenon.

3.速度:濟(jì)南模具加工的速度的快慢決定原料在模具澆道內(nèi)及成品中之狀況,快有毛邊,過(guò)飽,燒焦,慢了出現(xiàn)短射,縮水,結(jié)合不良易斷等。 Speed: the speed of mold processing in Ji'nan determines the raw material in the mold and the situation in the finished product, fast edge, too full, burnt, slow the emergence of short shot, shrink, combined with bad easily broken.

4.溫度:原料不同,溫度各異,太低溶液膠顏色不均,成品內(nèi)應(yīng)力增大.因溫度過(guò)低增壓過(guò)高,可能引起螺桿斷裂,過(guò)高,產(chǎn)品有毛邊,又因冷卻產(chǎn)生溫差,引起收縮。此時(shí),濟(jì)南模具加工的原料會(huì)分解,變黃,變色,易斷裂.冷卻時(shí)間變長(zhǎng),氣不容易排出,會(huì)有瓦斯氣。Temperature: different materials, different temperature is too low, uneven color glue solution, the finished internal stress increases. Because the low temperature may cause excessive pressure, screw fracture, high product, a flash, because of cooling temperature difference, cause contraction. At this point, the Ji'nan mold processing materials will decompose, yellowing, discoloration, easy to break. Cooling time becomes longer, gas is not easy to discharge, there will be gas.

推薦注塑加工產(chǎn)品

推薦注塑加工資訊

- 濟(jì)南注塑加工采用多軸數(shù)控的優(yōu)點(diǎn)

- 山東模具加工有哪些特點(diǎn)?

- 如何降低濟(jì)南注塑加工時(shí)出現(xiàn)的誤差?

- 小型濟(jì)南注塑加工模具廠的管理體系重要嗎?

- 濟(jì)南注塑模具加工過(guò)程中的疑難雜癥如何解決

- 濟(jì)南注塑模具加工過(guò)程中的數(shù)據(jù)管理

- 模具加工銀紋如何解決?

- 濟(jì)南注塑加工廠如何評(píng)估小型注塑模具價(jià)格

- 判斷濟(jì)南塑料注塑加工質(zhì)量好壞的三種方法

- 濟(jì)南注塑加工中制品填充不足的原因

- 濟(jì)南注塑模具加工需要我們自己完成設(shè)計(jì)嗎

- 濟(jì)南注塑加工廠介紹藍(lán)牙耳機(jī)注塑模具一般多少錢(qián)一套?

- 濟(jì)南注塑加工廠有帶料加工的嗎?

- 濟(jì)南注塑加工廠塑料模具設(shè)計(jì)審核的內(nèi)容與方法

- 山東模具加工調(diào)試前如何做好準(zhǔn)備?

- 山東注塑加工中制品填充不足的原因

- 濟(jì)南注塑加工廠介紹開(kāi)注塑成型模具要多少錢(qián)?

- 濟(jì)南注塑加工時(shí)涂層被覆解決方案

- 什么叫濟(jì)南注塑加工模具結(jié)構(gòu)的牛角入水?

- 濟(jì)南注塑模具產(chǎn)品前期應(yīng)該注意的事項(xiàng)