推薦產(chǎn)品

聯(lián)系我們

熱線:0531-84223080

手機:188-5310-7177 高經(jīng)理

手機:188-8831-9177 王凱

郵編:251400

地址:濟南市濟陽縣濟北開發(fā)區(qū)黃河大街智造小鎮(zhèn)G1

新聞中心

山東注塑加工過程中如何散熱?

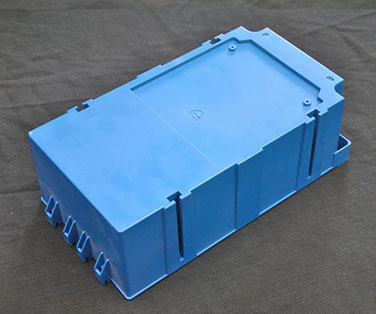

瀏覽次數(shù):818 發(fā)表時間:2017-04-27 14:59:48山東注塑加工中的塑料制品在我們的生活中很常見,使用塑料外殼的產(chǎn)品更是多得數(shù)不勝數(shù)。塑料外殼加工的方式與普通塑料制品的加工原理是一樣的,但在要求上還是有一些不同的。下面我們便來簡單介紹下塑料外殼加工的散熱問題。Plastic injection molding process in Shandong is very common in our lives, the use of plastic housing products are numerous. Plastic shell processing and ordinary plastic products processing principle is the same, but there are still some different requirements. Here we will briefly introduce the plastic shell processing of heat dissipation.

在山東注塑加工的注塑外殼加工過程中熱量的散失是一個必須要考慮的一個重要方面,通常熱量的散失是由于其傳遞的不間斷性造成的。在注塑生產(chǎn)之時熱的傳遞方式主要有輻射、對流和傳導(dǎo)三種,除了大部分被模具吸收之外,還有一部分是通過輻射、對流的方式散發(fā)到空氣之中的。The heat dissipation is an important aspect to be considered in the injection molding process of plastic injection molding in Shandong, and the loss of heat is usually due to the continuity of the transmission. In the injection molding of the heat transfer mode is mainly radiation, convection and conduction three, in addition to most of the absorption by the mold, but also part of the way through the radiation, convection into the air.

山東注塑加工廠家認(rèn)為,在塑料外殼加工成型的時候需要提高熱量的利用率,而在成型冷卻的時候,則需要較快的降低溫度,這個就需要冷卻模具上戰(zhàn)場了,通常冷卻采用的介質(zhì)是水,緣由是水價格低,成本自然也就低,冷卻過后的水源可以循環(huán)利用。但是畢竟凡事都有利有弊,低價格與可循選使得其只能作為初級冷卻劑來使。Shandong plastic processing factory, when the plastic shell molding process to improve the utilization rate of the heat, and when the molding requires cooling, temperature decreases quickly, this requires cooling die on the battlefield, usually by the cooling medium is water, the reason is the price of water is low, the cost is naturally low, cooling after the water can be recycled. But after all, everything is low price and choose to follow There are both advantages and disadvantages., makes it only as a primary coolant to.

山東注塑加工廠家提醒,如果想要達到最佳冷卻效果還是需要冷模上場的,在這里需要特別提醒的一點是并不是冷卻劑越冷越好,物極必反,過冷可能會出現(xiàn)反效果。Shandong plastic processing factory to remind, if you want to achieve the best cooling effect still need cold play, here needs to point to remind the coolant is not as cold as possible, however, too cold may cause negative effects.

推薦注塑加工資訊

- 濟南注塑加工中塑料制品熔接痕的產(chǎn)生原因式什么

- 注塑模具結(jié)構(gòu)與維護事項

- 了解濟南注塑加工上下模具的要點

- 濟南注塑加工廠如何在15天時間完成高質(zhì)量塑膠模具呢?

- 山東注塑加工的結(jié)構(gòu)設(shè)計要點

- 濟南注塑加工液壓油污染和開模聲音過大原因分析

- 濟南注塑加工廠介紹模具制作流程

- 塑料制品加工時需要涉及到那些工藝參數(shù)?

- 濟南塑料模具廠盤點常用的塑料模具零件作用

- 濟南注塑加工廠介紹開一套注塑模具要多少錢

- 找濟南注塑模具制造廠選交期有保障的廠家

- 一般濟南注塑模具加工用什么鋼材好?

- 注塑加工行業(yè)的價格為什么會上漲

- 影響山東注塑加工精度的因素有哪些?

- 造成濟南注塑加工成本上漲的原因

- 制造注塑模具時要注意哪些問題?

- 注塑加工過程中銀絲產(chǎn)生的原因有哪些?

- 濟南注塑加工廠介紹注塑成型為什么要加擴散油擴散粉?

- 濟南注塑加工怎樣算成本?

- 山東模具加工廠如何管理?